3M™ Thermally Conductive Acrylic Interface Pad 5571

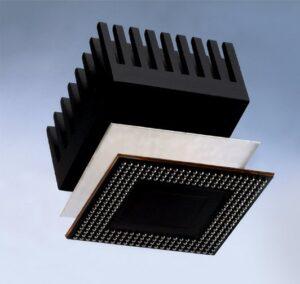

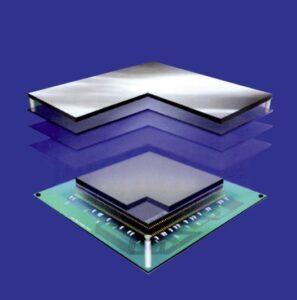

3M™ Thermally Conductive Acrylic Interface Pad 5571 is designed to provide a preferential heat transfer path between heat generating components like integrated circuits and heat spreaders (e.g. aluminum heat sink). 3M pad 5571 consists of a highly conformable, slightly tacky acrylic elastomeric sheet filled with conductive ceramic particles which provide features listed as follows:

Key Features

• High thermal conductivity, 2.0W/m-K on plane direction

• Good softness and conformability even to non-flat IC surfaces and heat spreading blocks

• Passes UL 94 V-0 flame retardance test

• No siloxane outgassing or oil bleeding

• Soft compliant material allows for pressure relaxation, preventing high pressure zones on components

• Good electrical insulation properties

• Slight tack allows easy pre-assembly

• Good wetting performance for better thermal conductivity

Product Construction/Material Description

Note: The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

Property | Value |

Color | Yellowish White |

Base Resin | Acrylic |

Pad Thickness | 0.75 mm/1.0 mm/1.5 mm/2.0 mm |

Primary Filler Type | Ceramic |

Product Liner | PET Film |

Roll Length | Standard: 33 m — Custom size can be supplied by user requests. |

Applications

- IC packaging heat conduction

- Heatsink interface

- COFchip heat conduction

- LEDboard TIM

- HDTV address IC chip and scan module board

- Generalgap filling in electronic device

- Mechanical fastening such as clamp, bracket, and screw can be used in parallel with this thermal conductive tape

Application Technique

- To obtain optimum thermal conductivity, good surfaces for wet out are required. For better contact, clean, dry and well unified surface conditions are recommended. Typical surface cleaning solvents are isopropyl alcohol and water (rubbing alcohol) or heptane.

Note: Be sure to follow manufacturer’s safety precautions and directions for use when using solvents. - Ideal application temperature range is from 0°C to 40°C. Initial application to surfaces at temperatures below 10°C is not recommended because the pad becomes too firm to be wet out readily. However, once properly applied, low temperature holding is generally satisfactory